Features forged from 4340 aircraft quality vacuum degassed material p n 15403 is made from 300m alloy with a flywheel horsepower range of 1 400.

Manley turbo tuff rods hp rating.

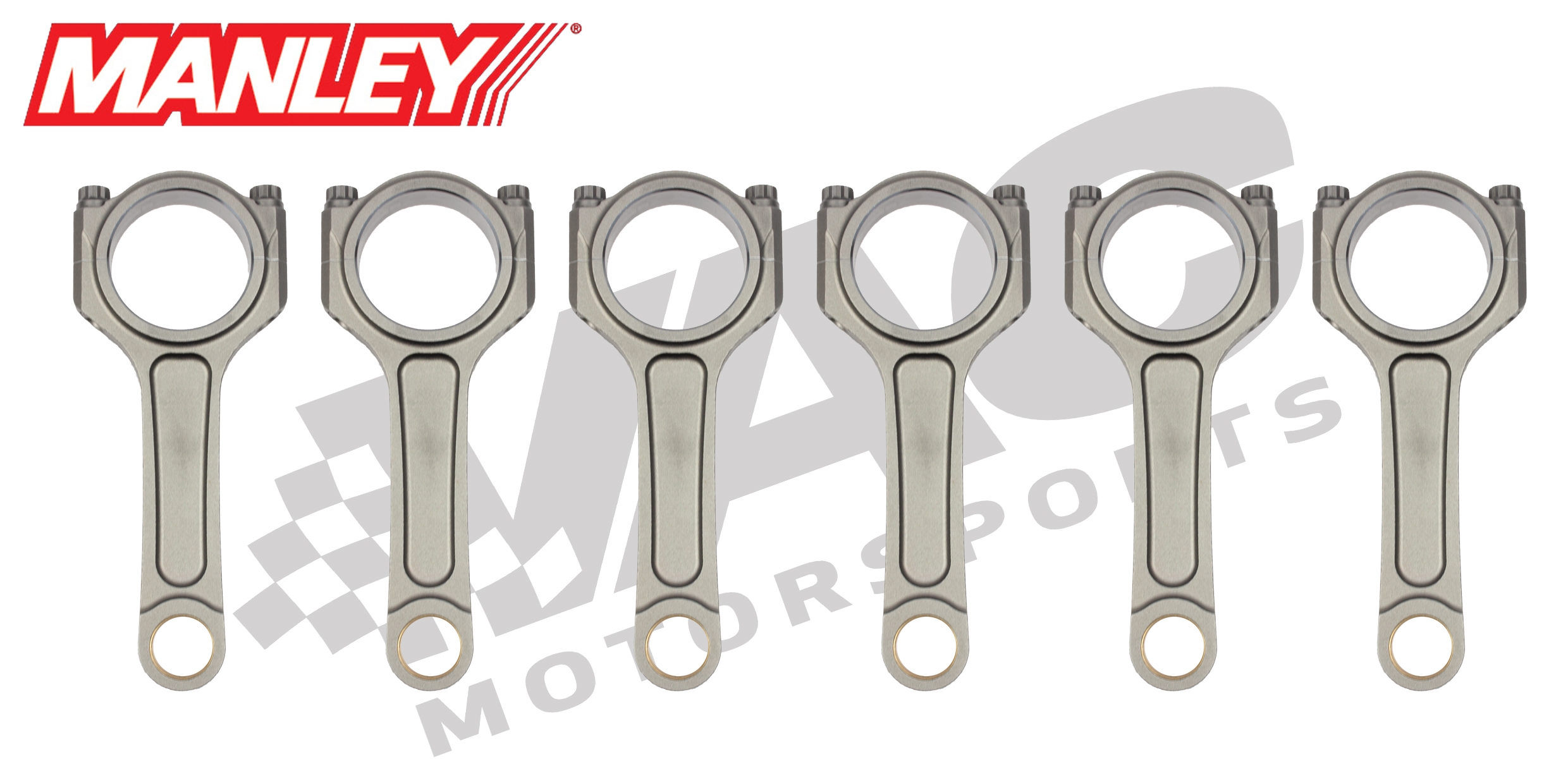

Manley pro series turbo tuff connecting rods are used by the best tuners in and outside of the united states in some of the fastest high horsepower heart stopping engines being produced.

Our designs range from feather lites tour lites lightweights standard weights and turbo tuff in 4340 aircraft quality alloy to our dirt series and dirt.

Unique features to the h tuff series include double ribbed pin surround and increased cross sectional thickness in critical areas.

Each rod is shot peened after machining and individually magnafluxed.

Manley pro series connecting rods are forged from aircraft quality 4340 steel.

The very best in the business.

Manley i beam turbo tuff.

Every rod is fully machined to the highest standards and the turbo tuff design combines the appropriate weight and rugged strength for ultimate horsepower utilization.

For a connecting rod that will handle higher boost and horsepower levels than a standard h beam.

If you are building a 800 plus hp engine than this is your connecting rod.

The manley pro series i beam rod has become the benchmark for high end connecting rods in the performance industry.

Each rod is fully machined in the manley lakewood nj factory to the highest standards.

Manley pro series connecting rods are forged from aircraft quality 4340 vacuum degassed material.

Cap fasteners are 3 8 arp 2000 for the h beam and 3 8 arp custom age 625 for the h plus.

The arp 625 rod bolt option bumps up hp rating to a whopping 800 out of an h beam rod.

Manley pro series i beam turbo tuff connecting rods are assembled from high quality 4340 forged steel.

Our signature turbo tuff design combines the appropriate weight and rugged strength for ultimate horsepower applications.